- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Food extruder application

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

Food extruder application

2019-01-18 13:43:11

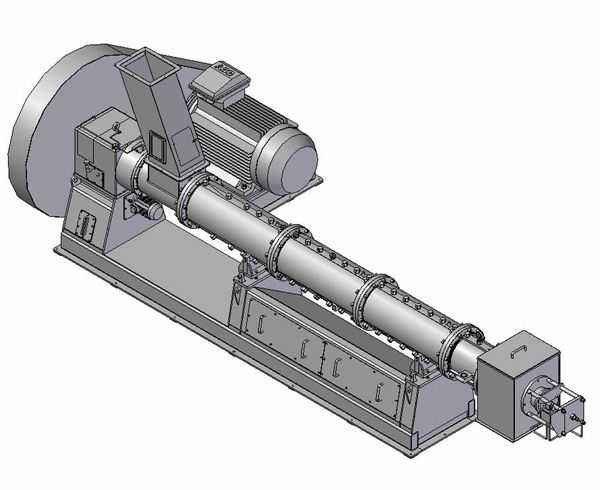

Based on the energy principle, quality principle and production principle, this paper establishes the equations needed in the similar design of food extruder, demonstrates the feasibility and reliability of similar design, compares the extrusion effect of the model machine and the testing machine, and finally gives The calculation results of a similar design of the twin-screw extruder.

Screw is widely used in food extrusion machinery. The design of the screw requires many assumptions and the theoretical model is not perfect. At present, it is still based on the experience design. Therefore, the design method of screw and its standardization have become one of the urgently needed topics in China. .

In the screw design of the twin-screw extruder, since the influence factors of the extrusion process are numerous, and the parameters often interact with each other, the twin-screw extruder designed according to the simplified assumption of the extrusion theory must be The structure of the screw can be modified and optimized during use to shape. The similar design theory is based on the study of the same part and the variation part of the similarity. Its research and application have played an important role in design methodology and manufacturing.

The related works and papers mention similar designs of screws, but they do not give a complete calculation process and calculation formula.

In this paper, various equations required for similar design of screw are derived. On this basis, a new type of experimental machine with similar screw is designed and manufactured with reference to foreign advanced large twin-screw extruder equipment, and the model machine has been optimized. The extrusion effect is more economical and practical than an extruder designed according to various empirical formulas.

The experimental results show that the twin-screw extruder experimental system works stably, and its specific energy consumption is 0.08 ~ 0.21 kW · h / kg, which can effectively use the motor torque (40 ~ 73). Practice has proved that the similar design of the screw of the twin-screw extrusion test machine has achieved good results.

It should be noted that the influence of the screw geometry on the physical properties of the extrusion process and its mechanism of action are still lack of in-depth study. The characteristic parameters of some of the infinite steel in the similar design of the screw are not likely to be reduced or enlarged indefinitely. Any size, the design should be limited to 1.5 to 3 times. The successful application of similar design on the screw has opened up a new way for the simulation theory to study in the extrusion process and related fields, which will accelerate the research process of food extrusion technology in China.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line