- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Study on palm kernel oil extraction process

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

Study on palm kernel oil extraction process

2019-01-14 13:50:00The physicochemical properties of palm kernel oil are very different from those of palm oil, but they are similar to coconut oil. The oil production process is not the same. This paper introduces the problems and improvement measures in palm oil extraction process and equipment debugging.

According to the variety, origin, fertilization and conservation, fruit age, the proportion of flesh, nut shell and fruit nucleus in fruit varies greatly, which is roughly 35%-80% of fruit pulp and 8%-20% of fruit shell. The nucleolus is 6% to 15%. The oil content in the pulp is 46% to 50%, the oil content in the nuts is 50% to 60%, the oil from the pulp is called “palm oil”, and the oil from the nut is called “palm kernel oil” and “brown”. Kernel oil or "brown nuclear oil".

Fresh palm kernel oil is milky white or yellowish, with a solid consistency and a desirable walnut aroma. Palm kernel oil contains a lot of low-grade fatty acids, which are very different from palm oil but similar to coconut oil. Due to its special fatty acid composition, palm kernel oil has high oxidative stability and its cholesterol-free and trans-fatty acid properties are particularly popular when used in refining products (saturation) for good health.

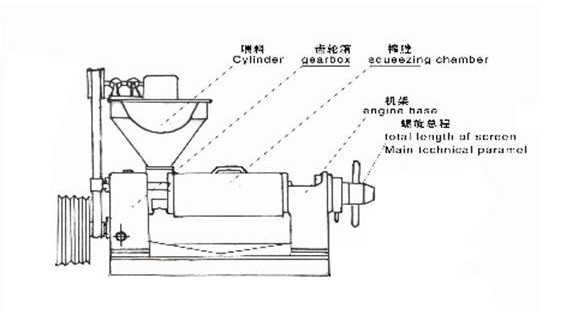

In places where palms are grown in Malaysia, Indonesia, etc., there are many palm oil plants and palm kernel oil plants, and the processes of oil plants are not the same. The main palm kernel press process is a secondary press process that ensures that the residual oil in the palm kernel cake is between 5% and 7%, but is limited by the small processing capacity of a single oil press and the large number of lines required in large production lines.

After years of development, China's large-scale oil extraction equipment has gradually matured, but due to the small amount of domestic palm kernel raw materials, there are not many applications, and foreign customers lack trust, especially for the oil press as the main engine of the oil press section. .

The oil press is applied in many oil press production lines at home and abroad, and has achieved good results. Its processing capacity can reach 280-300t/d for rapeseed, which is a mature product in domestic large-scale oil press. If the oil press can be successfully applied in the palm kernel oil press, it will help reduce the number of presses in the palm kernel oil plant and reduce the cost of business management.

In this paper, the palm kernel oil extraction process is briefly described, and the 1000t/d palm kernel one-time hot-press oil project is taken as an example to introduce the problems and solutions of equipment commissioning and share with the industry colleagues.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line