- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> New microwave vacuum dryer design

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

New microwave vacuum dryer design

2019-01-23 10:18:31

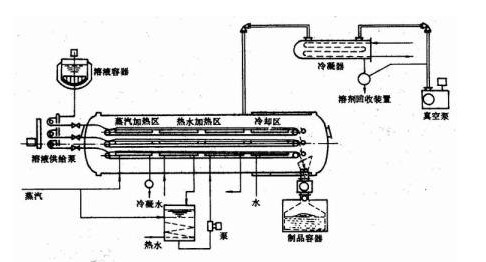

A new device integrating microwave drying and vacuum drying is designed. The waveguide and wave source cooling device are integrated into one, which effectively solves the two problems of uneven microwave distribution and easy damage of microwave source. The material chamber is the intersection of the microwave chamber and the vacuum chamber, so that the material can be both subjected to microwave radiation and in a vacuum environment.

The layered design of the material tray can be easily disassembled on the one hand, and the space of the material chamber can be fully utilized on the other hand. The modular cold trap design allows the cold trap to be freely loaded and unloaded according to the drying requirements, which can effectively improve the utilization efficiency of the cold trap. The microwave vacuum drying equipment is ingeniously designed, safe and reliable, and can meet the dry processing of high quality materials.

The microwave drying machine can heat the inside and outside of the material synchronously, and has the characteristics of fast drying speed and uniform drying. However, the drying temperature is generally above 70 °C, which is likely to cause gelatinization of the material. Vacuum drying allows the material to dry at a lower temperature, which protects the active ingredients of the heat sensitive material, but has a slow heat transfer rate and high drying cost.

Microwave vacuum drying is a new drying technology that integrates microwave drying and vacuum drying. It uses microwave as a heat source to overcome the shortcomings of slow heat conduction in vacuum drying. Drying the material under vacuum greatly reduces the drying temperature and protects the active ingredients in the material. Combined with the advantages of fast drying speed, good drying quality and low drying cost, it is a new drying technology with great development potential. This advantage makes it widely used in food, agricultural products and medicine.

Microwave vacuum drying equipment typically includes a drying chamber, a microwave system, a vacuum system, a measurement system, and a control system. According to the state of the materials in the equipment, it can be divided into static microwave vacuum drying equipment and dynamic microwave vacuum drying equipment. Static microwave vacuum drying equipment means that the material is stationary. A microwave vacuum drying device was designed to keep the material stationary. A microwave agitator was added under the microwave source to make the microwave more evenly applied to the material, but the disadvantage was that the materials that could be loaded were limited.

A pair of open-door microwave vacuum drying equipment was designed, which has a rectangular parallelepiped shape, and the material inlet and outlet are located at the front and rear ends of the box. The microwave generator is evenly distributed on the side of the tank, and the materials are loaded into a plurality of drying boxes, which are sequentially added from the inlet until they are full.

After the drying is completed, a new drying box of dry material is added, and the dried material is pushed out to the material outlet to solve the bottleneck problem of the drying equipment charging, but the material is stationary when it is dry, and the problem of uneven heating is likely to occur. The dynamic microwave vacuum drying equipment means that the material is moving. A continuous microwave vacuum drying device was developed to place the material on a continuously rotating shelf strip, and both the material and the shelf absorb microwave energy, thereby increasing the drying rate. However, the one-way movement of the shelf belt severely restricts the material.

Dry.

A drum-type microwave vacuum drying experimental equipment was designed. When working, the material moves with the drum, and the heat is evenly distributed, and the problem of hot spots can be avoided. However, due to the relative movement between the material and the drum, the material is easily damaged. In addition, water vapor tends to condense on the drum, affecting the quality of the dried product.

A microwave vacuum drying equipment was designed. A hexagonal wheel was installed in the vacuum chamber, and a material tray was installed at each corner of the hexagonal wheel. The material kept moving with the turntable, so that the material could be evenly heated. However, the microwave source can only be naturally cooled and easily damaged by heat. In response to this situation, this study specifically designed a microwave vacuum drying equipment. It integrates the wave source and the waveguide, and the material tray is layered. The cold trap is modularized, which effectively overcomes the shortcomings of the existing equipment, and is beneficial to microwave vacuum drying for wider application.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line