- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Development status of nut material shelling technology (1)

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

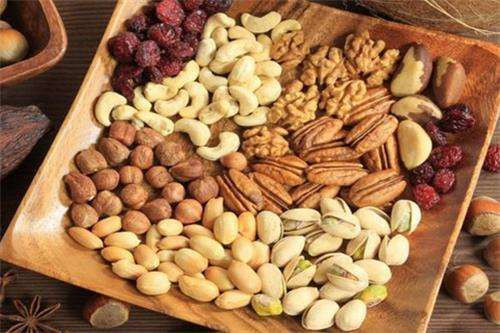

Development status of nut material shelling technology (1)

2019-01-17 13:59:551 nut agricultural material shelling process

In terms of shelling, in addition to research on the principle of shelling and equipment, people also studied the process to improve the shelling rate, the whole kernel rate and the shelling quality of nuts. The method of shelling is as follows:

(1) Adjustment of moisture: The moisture content of the nut has a great influence on the shelling effect. When the water content is large, the toughness of the outer shell increases. When the water content is too small, the powder has a large powder. Therefore, the nut should be kept as optimal as possible to ensure the maximum elastic deformation and plastic deformation of the outer shell and the nut, that is, the moisture content of the outer shell is so low that it has the greatest brittleness, and can be fully broken when shelled. To maintain the plasticity of the kernel, the seed kernel should not be too much powdered under the action of external force due to too little water, thereby reducing the breakage rate of the kernel.

(2) Freezing treatment: Due to the freezing treatment of the material, the material shell becomes hard and brittle to varying degrees. The rate of one-time shelling has been improved to varying degrees, and the rate of broken kernels has also decreased.

(3) Grading treatment: When the mechanical shell breaking method is adopted, since the nut material has a large particle size range, it must be classified according to the size and then shelled to increase the shelling rate and reduce the breaking rate.

(4) Microwave drying mechanical treatment: After drying the nuts, some of the water in the capillary structure of the shell is gradually removed first, and the adhesion between the shell and the nuts is gradually reduced, and the brittleness of the shell gradually becomes larger. The amount of deformation when the outer casing is broken is reduced, which is advantageous for improving the husking effect. Nut shell machine.

(5)Scoring on the outer surface of the nut: When the nut is broken, the outer shell of the nut is subjected to a force sufficient to break it, and under the force, the outer shell will be deformed. The smaller the deformation, the higher the rate of whole kernel obtained when broken. The surface of the outer surface of the nut shell before the shell is broken will significantly reduce the strength of the shell and reduce the deformation.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line