- Small Oil Pressing Machine - Leader Machinery

- Industrial automatic continuous fryer Soybean Oil Plant

Home> Company News> Flour processing technology and equipment

- Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Factory Address3rd Road, High-tech Zone, Jinan City, Shandong Province

- Worktime9:00--18:00

- Phone(Working Time)086-0531-885125

- Phone(Nonworking Time)086-0531-881256

- Fax086-0531-885125

Flour processing technology and equipment

2018-11-09 09:52:25

Before the reform and opening-up, the local people from generation to generation mostly depended on the variety of coarse grains as their main food; 30 years after the reform and opening-up, with the growth of material wealth, the grain could meet people's living needs, and the main food was the cake food of fine grains series, which was for tasting fresh food and keeping in good health. To prevent partial eclipse.

Nowadays, most of the ordinary families make cakes with market flour. Due to excessive fine processing, the nutritional loss is more. With the development of food processing industrialization and people's attention to balanced nutrition, how to adapt flour food equipment to the special needs of industrial production of cake food, and then develop and produce qualified cake flour has become an urgent task.

1 quality requirements for flour made from bread flour

Characteristics of pulverized coal mill and roller mill

1) stone milling

Stone grinder is composed of motor drive and screen surface installed on traditional stone grinding machine. The speed of grinding wheat is controlled by adjusting the speed of motor. The wheat is grinded into powder by rotating and extruding the grinding teeth of two grinding rolls. Stone milling is one of the commonly used methods to prepare whole wheat flour. Because of its low rotational speed, it can reduce the loss of nutrient components in wheat. Carotene, protein, gluten, carbohydrate, phosphorus, calcium, vitamins and other nutrients in wheat can be retained.

2) roller mill powder

Roller mill is suitable for large scale production with stable product quality. Compared with stone mill, roller mill has the advantages of high output, convenient operation, low temperature rise of material in the process of processing, energy saving and high efficiency. Moreover, the roller mill is a kind of stereotyping equipment, which can be followed by the national standards in making, and can ensure the stable and reliable quality of the flour produced.

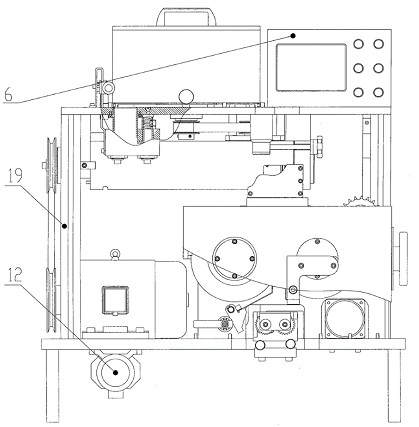

2 special processing equipment

1) microwave drying machine flour milling machine.

As the core equipment of this kind of flour production process, flour mill is a kind of high-yield and energy-saving equipment driven by two motors, which has the characteristics of safety, sanitation and reliability.

When different grinding systems are used, the flour mill can produce all kinds of high quality flour, including whole wheat flour, black flour and standard bread flour.

2) AirEco gravity grading screen

AirEco gravity grading sieve adopts multi-layer adjustable angle sieve surface structure, which is compact and widely used. It is used to remove the fine bran of flour. The special suction mechanism minimizes the consumption of wind energy, discharges materials by self-flow, and is hygienic and safe. Pulverizing process

1) conventional milling technology

The cleaning process includes three sieving, one stone removal, one moistening and one slight peeling. The milling process is first pre-crushed by a roller mill, then grinded by a flour mill, and then conveyed by a hoist to a high square screen for pre-sieving, then classified and removed by an AirEco gravity grading sieve, and finally the bran is removed. Horizontal centrifugal screening is used to enter the silo for temporary storage, and materials in the temporary storage silo are packed into the baler for storage or shipment after leaving the silo.

2) flour milling technology based on grade powder production line.

Following the flour road technology of grade flour, the cleaning process is conventional three-way screening, two-way threshing, one-way stone removal, one-way color separation and two-time moistening. The crushed materials are put into the flour mill of flour equipment to grind. After grinding, the materials are transported to AirEco gravity grading sieve, sieving, grading and bran removal by elevator. After screening, the material is raised again and distributed through the distributor to the inspection screen to get the finished product.

3 conclusion

In order to improve the technical level of flour food processing, it is necessary to strengthen the extensive use of flour equipment, fine processing and ensure nutritional balance.

Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging

JiaHao machinery PVC Edge Band Sheet Production Line High intensity different color to choose producing PVC edge banging Wholesale products plastic extrusion machine for WPC flooring extrusion line

Wholesale products plastic extrusion machine for WPC flooring extrusion line Best Price Pizza Cone Machine / Pizza Making Machine Production Line

Best Price Pizza Cone Machine / Pizza Making Machine Production Line Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line

Factory Supply Dough Divider Cutting Dough Ball Pizza Dough Ball Machine/Bread Production Line